Thermally Conductive Polymers

The Challenge

Metal heat exchangers have long been the standard for thermal management, but they come with significant limitations. While they transfer heat efficiently, these traditional materials:

- Are heavy, adding unnecessary weight.

- Have high embodied carbon, contributing to environmental concerns.

- Lack versatility in design.

- Offer no corrosion resistance, leading to potential durability issues.

Although Thermally Conductive Polymers (TCPs) on the market attempt to address these problems, they often fall short, being:

- Brittle, making them prone to cracking.

- Offering low thermal conductivity, limiting their effectiveness.

- Unable to be mass-produced efficiently.

Our Solution

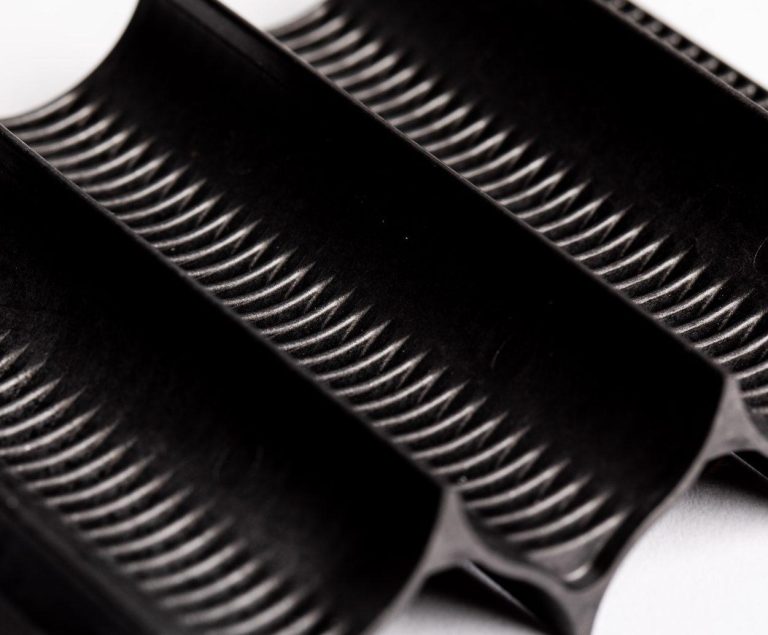

Senergy's patent-pending thermally conductive polymers are designed to overcome these challenges. Our innovative materials provide:

- Excellent thermal conductivity, rivaling that of metals.

- Scalability through injection moulding, profile extrusion, and thermoforming, making them ideal for mass production.

- Flexibility and durability, eliminating the brittleness seen in other TCPs.

By replacing aluminium with Senergy's TCPs, you can achieve:

- 30-45% reduction in weight.

- 500% lower CO₂ equivalent per product.

- 30% faster assembly times.

Senergy’s TCPs deliver performance, sustainability, and efficiency for the next generation of heat exchangers and thermal solutions.

Industry Sectors

Senergy’s thermally conductive polymers are supporting industry on its journey to a sustainable future within the automotive, energy and industrial sectors.

Automotive

Heat management solutions for the automotive industry, providing lightweight, low carbon and efficient alternatives to traditional metals.

Suitable for electronic housings, battery systems, LED lighting, and power electronics.

Energy

Thermally conductive polymers open up new opportunities for heat management in the energy sector, including design freedom, corrosion resistance and low weight.

Suitable for solar applications, battery systems, geothermal solutions and other uses.

Industrial

Corrosion resistance and cost-effective manufacturing are key interests for industrial heat exchangers made from thermally conductive plastics.

Suitable for heat exchanger tubing, fins and other components.

Services

At Senergy, we combine advanced Polymer Engineering with expert Design for Manufacture to deliver tailored, high-performance solutions. Our team specialises in developing customised polymer formulations for a variety of polymer processing techniques, ensuring each material is optimised for its intended application.

With our deep expertise in product and tooling design, we provide seamless, scalable solutions that meet the unique needs of our customers, from concept to production. This integrated approach ensures the highest levels of efficiency, innovation, and quality across the automotive, energy, and industrial sectors.

Polymer Engineering

Our expert team leverages core intellectual property and specialised knowledge to develop customised, innovative formulations for injection moulding, thermoforming, profile extrusion and compression moulding.

We deliver tailored solutions that offer:

• High thermal conductivity

• Electrical isolation

• Fire retardancy

• Enhanced processing efficiency

• Optimised additive replacements

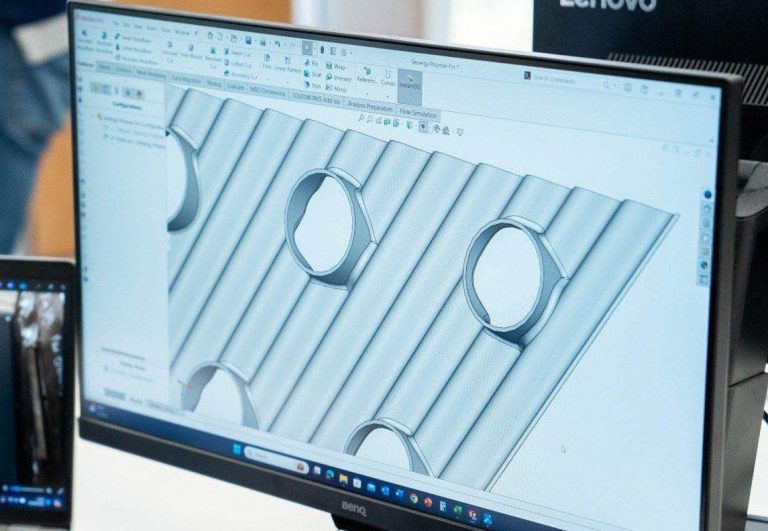

Design for Manufacture

Our knowledgeable team undertake detailed product and tooling design to deliver the optimal solution for our customers.

- Design specification

- Concept and prototyping

- Integration of multiple component parts

- Product design, 3D CAD

- Product heat transfer optimization

- Simulation - CFD, FEA, Moldflow

- Design for assembly

- Tool design and delivery

- Full project management

SenTherm Polymer Grades

Senergy offers a range of polymer grades to meet the varying needs of the automotive, energy and industrial sectors. Each grade is designed to meet specific performance and processing needs.

Choosing the correct polymer grade involves careful consideration of factors such as part design, end application, environmental conditions, and processing method. We encourage you to consult with our product design and polymer engineering team, who can guide you in selecting the best polymer grade for your product.

Meet the Senergy Team

We Dream Design & Deliver